New Desalination Technology

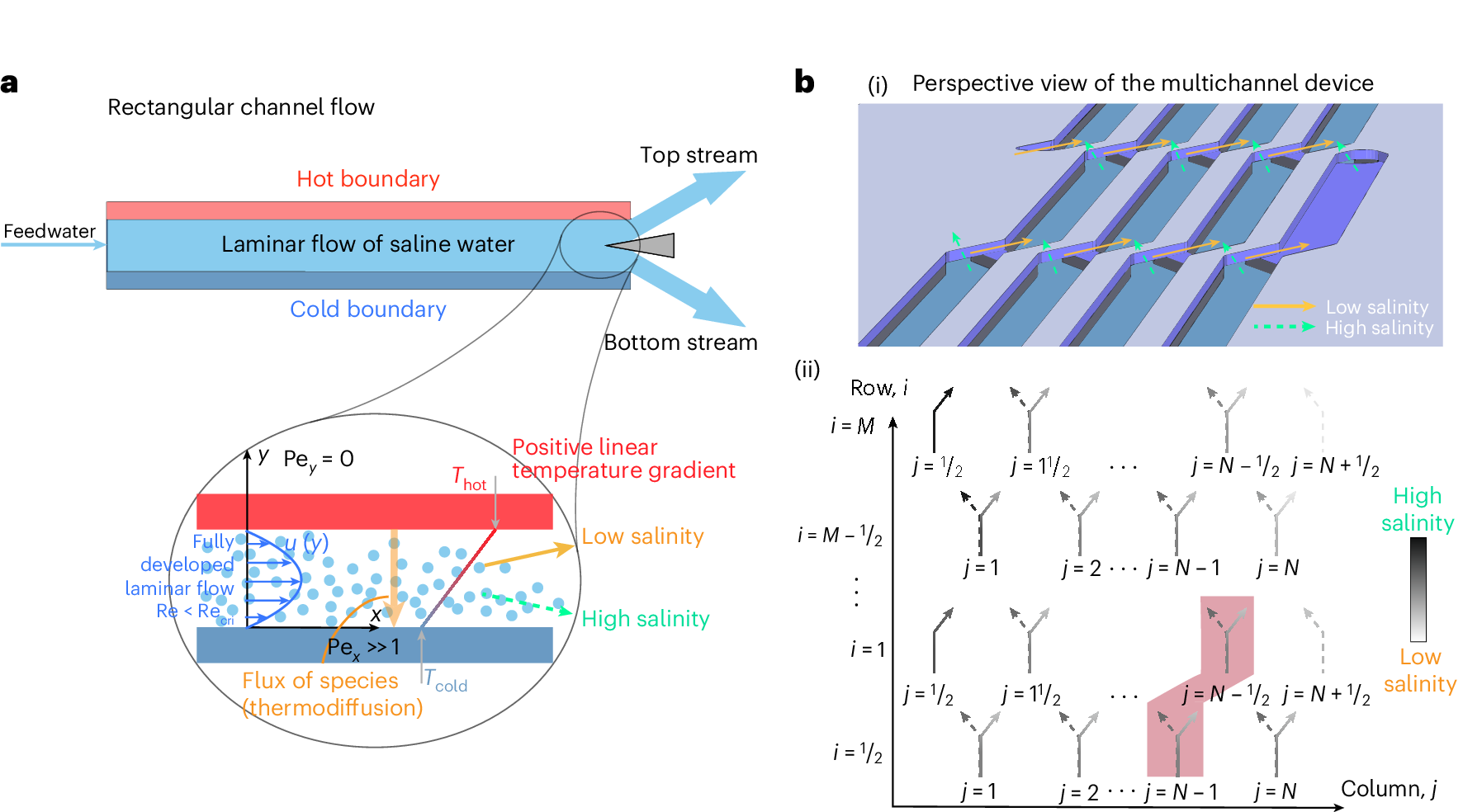

Australian researchers have developed a new desalination process that uses less energy than phase change and requires less maintenance than reverse osmosis.

We once saw a radio science program host demonstrate just how little of the world’s water is available to humanity to use for agriculture and consumption. He started with a full glass of water and poured out most of it, representing salty seawater, then even more representing water locked up in glaciers and ice caps, and so on down until there was just a few drops left - less than one percent. It was a graphic illustration of the problem faced by a growing human population coupled with climate-change-driven drought and water scarcity. What to do besides be more careful with how we use what we’ve got?

What about all that seawater? The UN estimates that about 40% of the world’s population lives within 100 km (62 miles) of a sea coast. If you could get the salt out of the seawater there should be enough for everyone. Some countries are doing just that. There are two main ways to accomplish it. The first is by phase change —boiling it or freezing, leaving the salt behind and retaining the fresh water. Producing a phase change in water requires a lot of energy. The second is by material methods like reverse osmosis — building up high pressure (about the same amount as in the cylinder of a race car internal combustion engine) on one side of a high-tech membrane so that the salt stays behind and the fresh water is forced through. While that takes less energy than a phase change, the membranes are prone to clogging and degrading.

The process still requires heat, but much lower grade, about 60 °C, which is more readily available from thermal solar panels or waste industrial processes.

Just as important, the manufacturing techniques needed for the system are relatively low-tech and could be produced locally via 3D printing and machine shops. While this development is still at lab scale, it’s an encouraging development.

Reading

Xu, Shuqi, and Juan F. Torres. “All-Liquid Thermal Desalination and Brine Concentration via Multichannel Thermodiffusion.” Nature Water, May 1, 2025, 1–15. https://doi.org/10.1038/s44221-025-00428-5.